Fiber + Dyneema® Composite Fabrics (Formerly Cuben Fiber) Technology

HERALDED AS THE MOST REVOLUTIONARY NEW MATERIAL TECHNOLOGY AVAILABLE FOR OUTDOOR GEAR, DYNEEMA® COMPOSITE FABRICS (FORMERLY CUBEN FIBER) ARE ELEVATING THE PERFORMANCE OF PACKS, SHELTERS, AND OUTERWEAR TO EXCEPTIONAL LEVELS.

TO BETTER HELP YOU UNDERSTAND THE TERMINOLOGY AND MATERIAL DESIGNATIONS YOU'LL FIND THROUGHOUT OUR SITE, WE'VE PUT TOGETHER A GUIDE TO THE DIFFERENT DYNEEMA® COMPOSITE FABRICS THAT WE USE TO CONSTRUCT OUR PRODUCTS.

DYNEEMA® FIBER

Technically classified as ultra-high-molecular-weight polyethylene (UHMWPE), Dyneema® fibers are produced by extruding a UV-resistant polyethylene gel through a spinneret. In a patented process, the fiber is drawn, heated, stretched, and cooled. The result is a filament with exceptional long-chain molecular alignment and high crystallization that limits density while allowing for uncommon load dispersion. At one-thousandth of an inch in thickness, Dyneema® has a remarkable strength-to-weight ratio that makes it the strongest fiber in the world.

Fifteen times stronger than high-quality steel, lightweight, extremely durable, waterproof and resistant to UV light and chemicals, Dyneema® fiber is increasingly used in industries where strength and dependability matter most—from military and law enforcement (personal and vehicle armor), the maritime industry (mooring ropes), and commercial fishing (lines and nets).

The Dyneema® fiber and fabrics we use are primarily manufactured in Arizona and North Carolina.

DYNEEMA® COMPOSITE FABRICS (FORMERLY CUBEN FIBER)

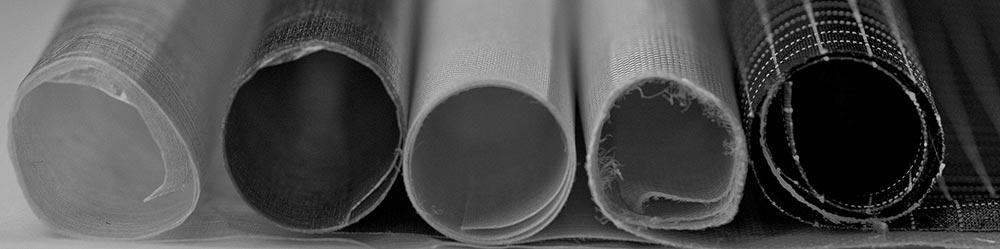

Dyneema® Composite Fabrics are high-performance, non-woven, rip-stop, composite laminates. Dyneema® fiber is laid out in opposing grid orientations, sandwiched between thin outer layers of polyester film, and melded together in a high-pressure autoclave.

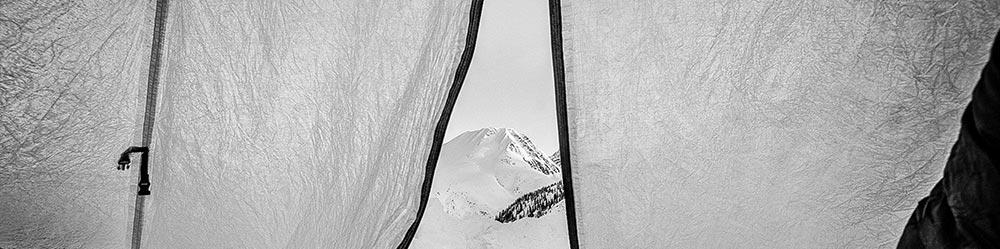

Dyneema® Composite Fabrics are highly durable but light enough to float on water. The material's unique properties allow for continual flex at stress points without compromising strength or structural integrity. Lighter than Silnylon but stronger than Kevlar, Dyneema® Composite Fabrics are 100% waterproof prior to stitching with high chemical and UV resistance.

Originally designed for use in high tech sails for America's Cup racing boats, and marketed as Cuben Fiber, Dyneema® Composite Fabrics are regarded as the premium material of choice for modern ultralight tents, backpacking tarps, and stuff sacks.

DCF8: 0.8 oz/yd2 // 26 g/m2

Used in: Ultamid 2, Ultamid 4, Echo II Shelter System, Flat Tarps, Drawstring Stuff Sacks, + Stuff Sack Pillows.

DCF11: 1.3 oz/yd2 // 43 g/m2

Used in: Pods, Drawstring Stuff Sacks, Roll-Top Stuff Sacks, Stuff Pack, and all Shelter Inserts.

DCF-WPB: 1.2 oz/yd2 // 40 g/m2

Used in: Dirigo 2

DYNEEMA® COMPOSITE HYBRIDS (FORMERLY CUBEN FIBER HYBRIDS)

We use two primary face fabrics in the construction of our backpacks, daypacks, tote bags and assorted accessories. These materials, which include lightweight Polyester (50-Denier or 150-Denier), or a 100% Woven-Dyneema® (375-Denier), are then laminated with Dyneema® Composite Fabric backings. This results in high resistance to abrasion, exceptional strength, superior rip-stop properties, and the moisture impermeability Dyneema® Composite Fabrics are known for.

While Dyneema® Composite Fabrics are 100% waterproof on their own, stitching creates small holes in any material. While we seal over 90% of seams, our packs are not 100% waterproof and should not be treated as dry bags. For near-total protection from the elements, redundancy within your pack using our highly water-resistant 100% Dyneema® Composite Fabric Pods and Stuff Sacks will help ensure that your gear stays dry.

DCH50: 3.5 oz/yd2 // 120 g/m2

50-Denier White: 2400 + 3400 Pack Bodies, Metro + Summit Pack

DCH150: 5.0 oz/yd2 // 170 g/m2

150-Denier Black: 2400 + 3400 Pack Bodies, Daybreak, Metro + Summit Pack

150-Denier White: 4400 Packs.

DCHW: 5.0 oz/yd2 // 170 g/m2

375-Denier White: Summit Pack, Duffel Bag, 5400 Porter, Dyneema® 2400 Ice pack

HARDLINE WITH DYNEEMA®

We also use our Hardline with Dyneema® fabric on the hip belts and shoulder straps of our 2400, 3400, 4400 packs, all exterior pockets on the Southwest pack, and the crampon/tool attachment panels on the Ice Pack. In this material, ultra-high-molecular polyethylene (UHMWPE) fiber is actually woven into the nylon fabric base for additional tensile strength. Hardline with Dyneema® is coated with a water-resistant backing but does not offer the same level of impermeability as the Dyneema® Composite Fabrics used elsewhere throughout our packs.